Ensuring High Performance: Dingfei’s Advanced Testing for Reflective Materials

At Dingfei Reflective Materials, quality and reliability are at the core of everything we produce. To ensure that our reflective tapes and films meet international safety standards and perform reliably in real-world conditions, we have established a comprehensive testing system that covers retroreflectivity, chromaticity, and outdoor durability.

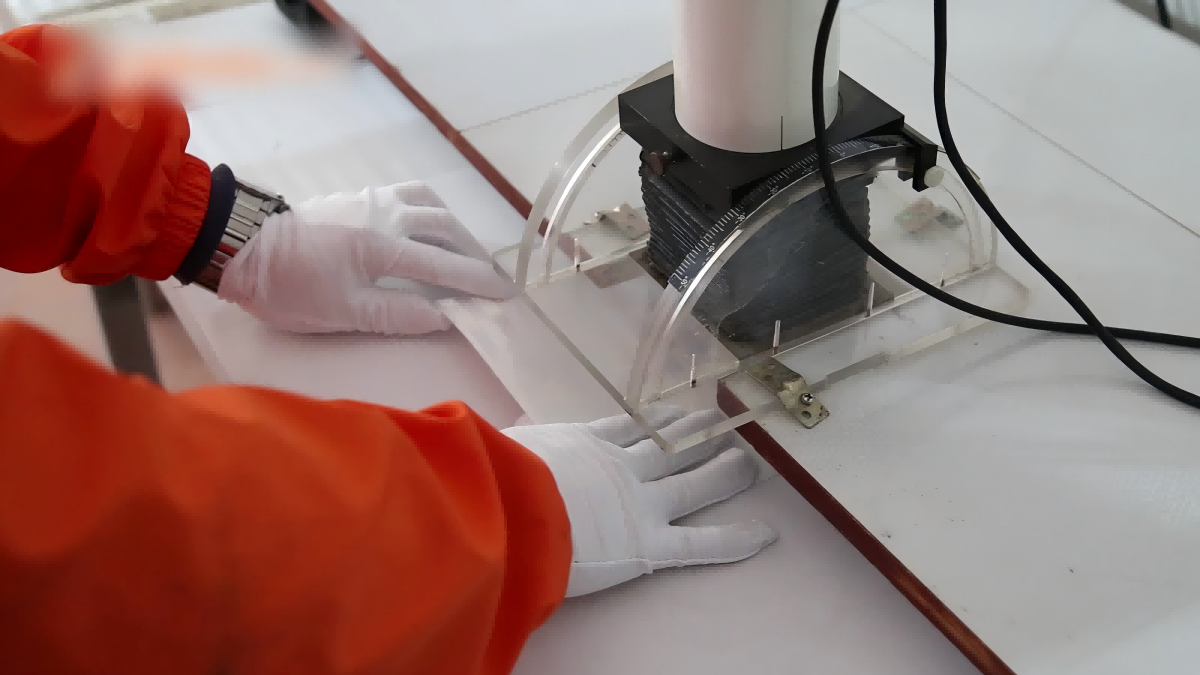

1. Retroreflectivity Testing with RoadVista 932

Dingfei is equipped with the RoadVista 932 retroreflectometer, a professional-grade instrument used to measure the brightness of reflective materials under standardized light and observation angles. This allows our quality control team to assess the retroreflective performance of each product batch, ensuring they meet standards such as ASTM D4956, EN 12899-1, and more. Whether for road signs, safety vests, or industrial markings, high visibility is guaranteed.

2. Chromaticity Testing with Precision Colorimeter

Color accuracy is critical in reflective materials, especially for traffic and safety applications. To maintain strict control over color compliance, we utilize a precision colorimeter to measure the chromaticity coordinates of our reflective films. This ensures that our products stay within regulated color zones and maintain consistent visual appearance across different lighting conditions.

3. Outdoor Open-Air Testing Zone

To simulate real-world conditions, Dingfei maintains a dedicated open-air outdoor testing area where reflective films and tapes are exposed to natural sunlight, rain, and other environmental factors. This helps us evaluate long-term weather resistance, UV stability, and durability. Outdoor testing complements our lab-based assessments and helps us continuously improve product performance for tough environments.

With a full suite of testing equipment and outdoor validation, Dingfei is committed to delivering reflective materials that not only meet industry standards—but exceed customer expectations.